UK Lean Manufacturing Consultants

Want guidance on how to OPTIMISE, deliver MORE from your existing equipment and staff? Want to discover how to deliver on-time, every time?

Check out this page, contact us TODAY...

Operations Strategy Consulting

Helping Your Operations Team

Deliver The Business Strategy.

We help guide your Operations Teams on a path of Strategic

redesign & improvements.

Improving Process & People

to deliver your growth plans.

Prevent Your Operations Output From Getting Worse; Make Them Predictable

Making Your Operations As Productive & Efficient As Possible>

Align Your Operations Team With Your Business and Strategy Growth Targets

Whether you call it the Operations Strategy, the Manufacturing Strategy, Production Strategy, your operations strategy is critical to the future growth of your business, your organisation.

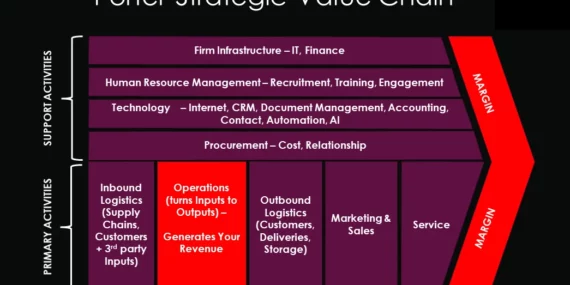

Operations are the team, the processes that turn the inputs into the outputs. The way your Operations team work, the processes they use, the costs they incur are critical to the your business, to delivering for your customers. They will be where you incur the largest costs for staffing, for technology (equipment and systems); be the area where the customer promises are delivered from, the team who actually deliver the products and services that deliver your revenue.

To develop your Operations model, to deliver the growth you think is out there, you’d like a guiding hand. For a start everyone has their day job, they are time poor to dedicate time to this activity. They’ve also got experience of what you do but what about ideas, best practices from outside? How can you challenge them to deliver for the future.

Your choice of Operations, Manufacturing Strategy and how to implement it to will have implications for your potential growth.

For instance there are 5 different Operational Business Models you can adopt; most businesses need to consider at least two of these. These models are typically;

Why do we say you need to consider 2 models?

As an example, if you sell Capital Equipment, it may be sold with a lead time, made to order.

You might also provide spare parts and servicing options for this equipment; these are likely to be needed quickly, picked from stock. Balancing an operation that makes equipment available immediately, from stock and based on specific orders requires different thinking BUT can be completed when you know how.

The choice of Operational Process or model above has implications across many parts of the organisation and changes the choices you make.

Areas that your Operations Strategy can impact include; you’re looking

We’ve learnt that in many organisations the Operations Teams struggle to deliver the Sales Targets. What if this is holding you back?

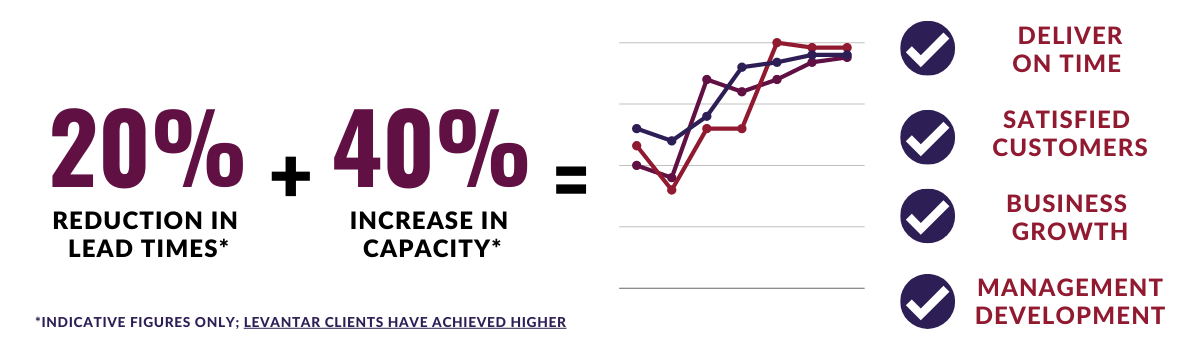

We’ve developed Operations Management processes and services that helps firms to deliver quality work, faster, on time, at lower costs whilst overcoming the skills challenges many face in 2022.

Giving you the reassurance that your Operations team can deliver now and grow with your business plans, your operations strategy.

levantar (verb) – to lift, to raise up

Working with Levantar the client identified how the production times could be cut by 50%. This gave the business the springboard to increase its UK and International sales.

The result of our programme was a business which delivered more output 40%, on time, in shorter lead times, without needing any more staff, or space in which to do it.

Sales increased by over 40% without additional staff costs.

They could compete on lead times with others in the market and be confident they could achieve delivery dates, every time.

Levantar discovered that the processing of client files took over 250 days. This mattered as they were only paid once this was complete.

Working with the management team a series of key improvement plans where devised; without the need to change any technology.

The result? the client files now take 120 days, less than half the 250 at the start.

This has allowed the growth plans to be implemented and has improved the cash flow; the money is coming in from clients in half the time.

As well as driving the Customer Satisfaction higher, the business also discovered that the programmes drove their measured Employee Engagement scores higher.

Levantar identified a programme of work which included managers, supervisors and team leaders in the design and execution.

The Levantar programme helped the team to devise ways of delivering 100% of the plan AND 35% more output without needing any more staff or space.

The programme was delivered through a number of small learning workshops (1-2 hours) and on-job coaching and feedback with managers and staff.

Improvement ideas & adoption and staff engagement is now central to how this organisation works every day.

Leeds University – Lean Management Workshops

Since 2010 we’ve taken well over 2,750 people through our Lean Manufacturing and Management workshop thanks to the Operations and Supply Chain team at Leeds University Business School.

Operations Strategy Consulting

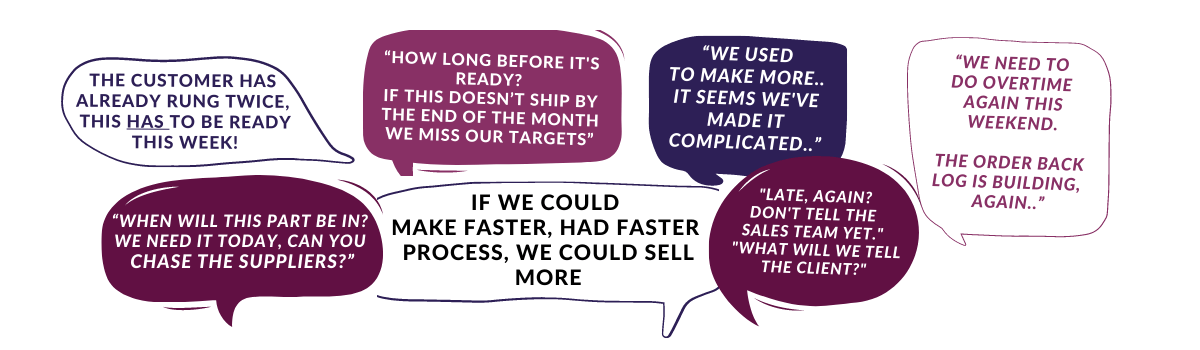

Read the comments below, do you hear these or similar in your organisation?

They’re the conversations we hear every day when we are out and about starting with clients. Clients who are discovering the benefits of Lean Management.

Want guidance on how to OPTIMISE, deliver MORE from your existing equipment and staff? Want to discover how to deliver on-time, every time?

Check out this page, contact us TODAY...

Need help to stabilise the Operational output in your business? Need someone with experience and the ability to roll sleeves up, step in quickly and start delivering? Help to stabilise your operations before making improvements?

Check out this page and contact us TODAY...

Want to up-skill your Operations staff? want to give them production skills that will enable YOU to deliver MORE? Our Lean training WILL BE built around your business needs, using the right techniques that will improve your business.

Check out the link and get in touch

We help you re-invigorate and optimise your processes; speeding them up, increasing Business Capacity & Compliance. Giving you agile processes that will deliver your business growth.

Click Below and get in touch.

Want Manufacturing advice? Not sure what you need to do, whether Lean is for you? Want to know if new processes or investment would be better, whether MRP would deliver what you need?

Check out this page and pick up the phone - it's free to have a chat.

Your Operations Team, your Operations Investments are the ones responsible for delivering for the customer. They take the inputs; raw materials, assemblies, reports, data - make changes, do their work and produce the output for your customers. The output that drives your revenue.

It is likely you employ the most people in your operations teams, you have the largest assets in the operations teams (machines, software, factory space) and they spend the most on inputs (stock, raw materials, reports). Having a plan, a strategy for these would seem sensible. Matching this strategy to your Business Strategy is key to ensuring everyone is heading in the same direction.

It could be that your Operations Team can give you options that enhance your Business Strategy, enhance the offer to the customers. Even allowing you to grow faster or with lower investments than you thought.

An Operations Strategy should underpin your Business Strategy. It should include sections on how you'll deliver your strategy whether that this is a Cost Leadership Strategy, Quality Leadership, Product Differentiation or Time Based Strategy.

The Operations Strategy should address People; Technology & Process; Systems; KPIs & Measures - how will you measure your outputs? know whether you are being productive? Behaviours - how do you want people to behave in the future; more self management? remote working? There are other areas you can address such as Costs - how will you cost products going forward? On a Throughput basis or Material + Labour + Margin for individual pieces of work. Whatever you include it's likely to impact on the strategy for other areas of the business such as HR, L&D, Finance, IT etc.